We wrote an article on robotic bending before. But because we like this theme, we would like to make a new one. Maybe we will repeat some thoughts, but probably you can even do something new from it. Let us start from the beginning.

The robotic bending of the press brake is the process where the operator is replaced by the robot. The robot performs the functions of holding the parts, positioning the parts, feeding the parts, and taking them away after the bending. We will not discuss in this topic other possible functions like changing the bending tools by the robot because this function is available but not very popular.

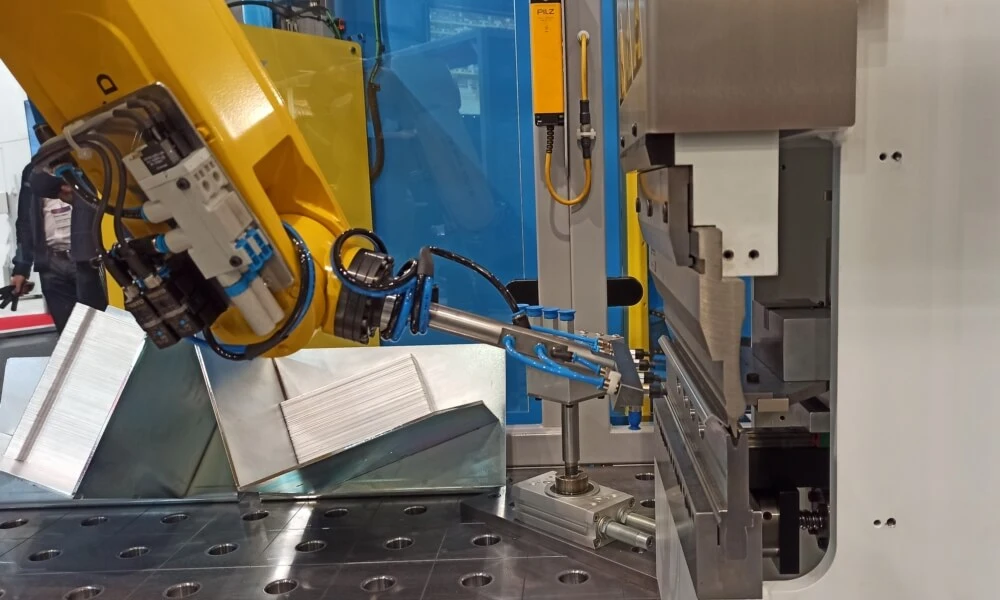

The press brake with the installed robot is usually called a “robotic bending cell.” The robot takes on the main operator function: take a plate from the batch, perform the right positioning with the special inclined table, then feed it into the press brake and position it where necessary. After the bending process, the robot moves the final part to another place for putting into the batch and removal from a robotic cell in the future.

The robot completely replaces the operator, but the operator stays near the working cell for necessary programming and main control, bringing in the pieces to bend and to remove the prepared parts after. Meanwhile, because it is not a constant job, it is more reasonable to call it control and programming plus material handling functions. In this mode, even one operator can control several bending cells. He will have time to do other necessary jobs, so it is a great boost for personnel functions at the factory.

Advantages of automatic bending

There is a general advantage of robotic bending, and it is very big: the complete automation process and the possibility to work in the mode 24/7. This means: without any limits, stops, or pauses, with high productivity and optimal precision. Robots cannot be tired, and they cannot lose concentration during the last hours of the work shift. Usually, such hours cause major mistakes due to tiredness. Also, the sheet metal parts could be medium or heavy; it is a big problem for the operator to handle them all the time. But heavy parts are not a problem for the robot based on their possible payloads and capacities. So the main advantage of robot bending is the same as any robotic production cell in the industry: making the functions faster, more precisely, and with a high level of productivity.

The second advantage of a robot is not typical but interesting—better to call it a construction advantage. Usually, the operator should position the part according to the position of the back gauge of the press brake, as necessary. If we are talking about the robot, it can position the part based on its program. In this way, the position of the back gauge is not so important compared to the work of the operator.

In this case, during the planning of the composition of the robotic bending cell, the expensive back gauge with six axes, for example, could be ignored and replaced with a more simple one. This allows for saving some costs for investment in the equipment. Theoretically, the press brake could be completely without the back gauge if we are talking about standard sheet metal parts and not very precise tolerances.

Installation of modern solutions

We would like to underline one more advantage of robotic cells, which is not clear to everybody. Automatic bending brings the factory to a new level; it is a high-technology process that is completely digital and effective. It is a positive picture for investors and customers, with great modern equipment that is completely safe and eco-friendly for the environment. We want to say that almost all modern robots are free of service, so they do not require ordinary maintenance to function.

Moreover, in the upcoming world of digitalization, the use of robots for human functions will provide complete and possible online control of them, checking of their actual status, traceable action, and the maximum possible efficiency and speed.

Disadvantages for bending automation

Well, all marketing information will not tell you, but there are disadvantages to robotic bending, and we would like to specify them. Maybe it helps anybody make the right choice and study the picture completely.

At first, the investment part. The installation of a robotic bending cell is much more expensive than just the installation of a press brake and inviting the operator to bend it. And we are not talking about the conditions where the robot is a necessary choice (for example, for heavy parts). We talk about economic efficiency and the realistic return on investment from the robot. So it will not be left as just an expensive toy at the factory.

The main reason to bend with the robot is a high quantity of completely equal production to bring more speed to the process of one or two types of parts. We can call this all redundant or excessive automation of the bending process, which finally will not make the production process more effective but more complicated. This means more expensive investments and the final cost of every single part, more difficult setup and use, and probably even slower bending of a complete batch of necessary parts for production.

Moreover, completely opposite will be the situation if there are medium or low volumes of equal parts and the assortment is quite large; finally, the robot will have a necessity for continuous reprogramming and a new setup, and the production effect will be very low.

Additional details of robotic cell composition

Also, robots have a lot of limitations. To handle the part, the robot has to have a special holder or fixator. Usually, it is a holding device with suction caps to take a part, or it is a mechanical gripper like a fork to clamp the piece from the edge. Small parts, holes, formings, and complicated geometry can make robotic bending very hard to realize or even impossible because of the impossibility of clamping.

Usually, the supply of robotic cells from the machine tool supplier or robotic integrator (the company that makes different solutions based on industrial robots) is based on the real production program and the development of holders and grippers. All parts of robotic cells could be universal, like positioning tables, positioners of pieces, safety devices, etc., but the holders should work exactly with your parts; otherwise, there is no reason to purchase the robotic cell. Also, robots, as you can imagine, have limits in their actions and possibilities.

So manufacturers of robotic cells implement additional robots, like separate ones, to change bending tools. On one side, the robot is quite a universal tool to install for a lot of functions with the proper auxiliary equipment and programming. On the other side, robotic functionality should be as simple as possible; in this case, it will provide the maximum efficiency. The operator can change the tooling in minutes, but if you make it automatic for the robotic cell, you should re-set up the complete process.

The supervision at the beginning of the work

One more story: the operator’s role is to perform a manual bending process on the machine. Contrary to robotic bending, imagine if there are no part control functions or machine vision and the robot makes a complete batch completely defective due to the mistake. The operator can make a mistake in the first 2-3 pieces to stop, but improper programming of the robot could lead to much bigger problems.

So we are coming to the conclusion that the robotic cell could be safe from problems and highly efficient if perfectly prepared for the work from the beginning. And because there is no man in the middle, a small mistake could lead to more troubles.

In the end, we can note that all automatic production is based on country and average salary as compared to the operator’s costs. The replacement with a robot could be much more effective and profitable in rich countries with large salaries. Anyway, the robotic bending process and automatic robotic bending cell today are part of Industry 4.0 and represent the modern technological situation. And it is also just beautiful and very attractive to watch. That is why you will find so many robots at industrial exhibitions of machine tools.