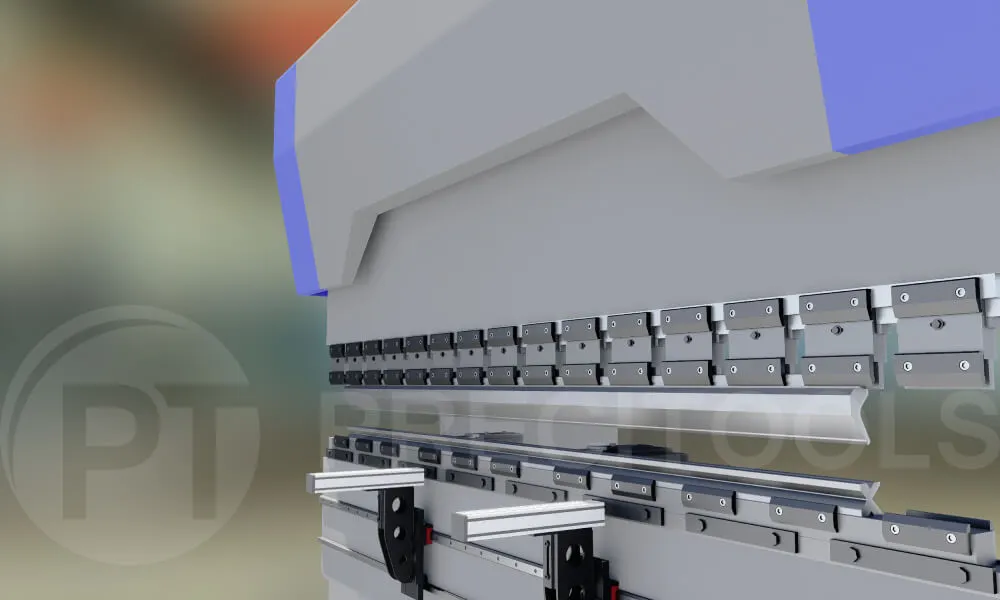

Visualization for the bending process

We already spoke before about how the digital environment and instruments can help during the manufacturing process with your press brake. In general, we are speaking about bending, but the same story could be true for any other manufacturing process.

We are working with bending tools, so we can explain how it was, for example, 30 years ago. The drawings of tools were made in scale 1:1 or bigger with a millimetrical grid, so you could take the drawing of the punch you want to purchase and try to draw it inside the part you want to bend to check the absence of any collisions.

We encountered until today this method of work, which we can call “old style,” but it is still working. But what could be the problem? Check the 2-degree spring back. Several bends to check? The job could be done; all drawings could be done manually, but it is really hard work.

For this task, simple 2D visualization could help. We are doing it with simple DXF drawings, and we have all the geometries of our bending tools. Customers make it with special bending software, and today a lot of CNC manufacturers offer at least 2D visualization for the operator before the bending. It is modern, simple, innovative, and finally saves a lot of time!

Solutions for old machines with digital instruments

The market today has thousands of used press brakes that could be 30–40 years old or more. They are still working, still making the parts, but for sure, there are no digital adjustments for them. But if you cannot do anything with your press brake (or you need to invest a lot to install a new CNC control, for example), you can request and prepare the ordinary tasks in a digital way, including all the maps, ways of bending, or control of the possibilities for new tools with parts intercollision.

The way of working could be different, from simple part drawings and punches inside the bend to the drawings of all the auxillary devices and parts like holders, supports, and the beam of the press brake itself for complete verification.

Today, with modern CAD systems, you can do a lot and even more. In a digital environment, you can even model the machine itself, the workfloor, and the composition of all elements and calculate any size you want, for example, for material transportation.

We already wrote a big article about bending software. But bending software is expensive and limited by a lot of things. Probably you have in your workshop the press brake of the manufacturer that no longer exists. When you ask about the possibility of including the model of such a press brake, we believe all the suppliers will be very stuck on offering the solution. But some customized modeling from the separate studio or even from us could be done without problems; just ask in a clear way.

Work with big parts

When you work with large parts, it is necessary to check for collisions with the press brake. But it is also necessary to check how the parts will be loaded into the machine, how they will be unloaded, the location of the storage of sheets before bending, the location of bended parts, and ways for material handling.

During the use of the bending software, you can check the correct bending with tools. But nothing will help you to check, for example, the position of bending followers. And it could be very important, too! It is a big job to check everything and be prepared. But it is very effective to prognose and verify all the risks before starting real production.

If you plan to install a robotic workcell or upgrade your press brake with a robot and automatic operations, you cannot ignore the preparation of the project in a digital environment if you do not want to catch all the problems after the installation. And it should be very precise and very professional. The robotic supplier should prepare the precise models for your press brake machine to have every dimension and to verify all the movements. And during the handling and work with big parts, it is much more important because everybody should verify that the parts can pass.

There is a very simple rule: you need to pay for design, models, and engineering, but if you do not do it, you probably have the risk of overpaying a lot more later.

Digitalization in the factory

Today, the industry enters the era of digitalization of manufacturing processes and the implementation of Industry 4.0. For these tasks, the production process is connected with computer software, machining software, part models, and technical processes. The achievement of the goal is a big cloud of everything from part drawing to the transfer of the part directly to the machine, control of the machine load, productivity, and all supplimentary operations.

But how can you insert your old machine into a digital environment? There are no available outputs to control the status online, for example. At least you can prepare in digital all your production processes for your press brake, all the operations, availability, and connection of available bending tooling. It helps not to get the actual status of the machine but to make complete management during the preparation for a new job and the opening of new orders. And it could be connected with the routes with the more modern bending machines to get the complete situation.

Digital instruments have one important task: to optimize manufacturing jobs and make them more effective.

Divide the jobs

We encounter a lot of cases where our customers have, for example, a bending machine where the operator is working, but for new orders, managers even do not know what they need. From our side, we are not experts in your production or in general production. But we are experts in bending, and it is better to ask us if you have any questions. We can decide later how to prepare your task in the most acceptable and effective way.

We do not like to study 20 drawings and replace the engineers of the factory for free. But we will be glad to assist you with a couple of parts. And we can make our recommendations with digital instruments. We can recommend the tools, but if you need more, we can even make modeling completely or partially digital on your machine, even if it is old. We can make visuals of production processes if you want to show them to your investors. Everything could be done. And use of digital instruments in our ordinary work are our main activity for today.