We have a long experience in tube bending in a lot of important sectors from the copper tube for air conditioning to aerospace applications. And we can tell for sure that tube bending is one of the most complicated sectors where you exactly do not know what machine is correct for your needs. So we want to make a new article about tube bending machinery and equipment.

Let us do a simple explanation: for example, you need to make a pump impeller on the machining center. You can do anything but 3 axis milling machine is not enough for this job and you will never do it. Moreover, if you need to make a simple part but the seller offers you a high-tech machining center at an expensive price it looks like a strange deal if you cannot find the advantages for your production to pay several times more.

We have met a lot of cases when for simple tubes incredibly expensive machines were offered. On the contrary — the customer wants to make a very complicated configuration but wants to buy it very simple and even semi-automatic or manual machine.

We know about real working installation when the park street furniture is made with a tube bending machine of more than 450 thousand EUR and a lot of aircraft parts are made with simple semi-automatic machines with the price of less than 50 thousand EUR.

What tube bending machine do you exactly need?

So how to understand what machine is reliable for you based on your production? Let us make the real sample from the life: tubes for livestock stall. There are two realistic and different installations — in France with the machine that costs today nearly 350 thousand EUR. And installation in China with the use of China origin machine cost nearly 50 thousand EUR. The same part and the same geometry. So we are not talking about something different.

So if we are talking about tube bending machines the factor which is the most important — not the geometry of the part but the quantity of the production. Even for simple tubes or simple assemblies, there are a lot of installations of automatic cells with a budget of 500–1000 thousand EUR due to the production quantity and necessary to reduce the cycle time to the minimum. But if we will look closer at the technologies to make the part we can understand that if the quantity of the production is small it is possible to reduce the purchasing costs and investments into the equipment several times.

Bent tube geometry

After the production factor, the next factor could be the part geometry but it is a very complicated question. First, with the automatic machine could be done everything that could be done with the semi-automatic tube bending machine but more budget choice will request the constant work of the operator during the bending.

Second — yes, there are complex geometries of tubes that could request double-head bending machines, rotation head bending, multiple axes involved, etc. And there are a lot of companies which are specialized mainly in these hi-tech tube bending machines which could have even 9,11,13 operational axis.

But we should note about internal production dialogue when the part was designed by the engineer without any notes of the bending possibilities and machinery details and just modification of the drawing and some enlargement of lengths could change the process completely and save a lot of money during the choosing of suitable tube bending machine.

Tube quality after the bending

The quality of tubes is one of the more topics for discussion. Everybody for sure wants the best possible quality and there is a lot of misunderstanding that the more expensive machine could bring a better quality of the bending. Moreover, it is true that a lot of times, the salesman also tells the same.

But mainly we should note that the most important the machine adjustment, setup, and alignment of the tube bending tooling so even with a simple machine sometimes it is possible to make much better results than with an expensive full automatic 13-axis machine if the complete setup was performed perfectly.

Anyway, the basis will be the following: more possible movements and adjustments allow us to make more fine adjustments, more precision setup, and finally – more possibilities for the perfect quality of the bent tube. A complete servo drive tube bending machine allows to program of the strokes of all movements of clamps and pressure dies and sometimes it will be extremely important for some applications.

Digitalization of tube bending process

Automatization and digitalization make the biggest advantage with the cutting of most operator’s functions to move the tube manually and allowing to prepare the programs even outside of the machine by sending them after through the factory’s network and bringing them with USB key. It allows also for engineers to organize the full digital process and even to deal directly with tube assembly models with flanges and additional elements and separate the bent tube to be sent into the tube bending machine.

Application of bending also values a lot.

For example, for furniture tubes and rails, the technology to use the tube bending together with the welding could be the most optimized way for the final result and possible investments. But if there are tubes for high pressure (for example hydraulic tubing) the most important is to reduce or eliminate the welding seams out of the part because each seam brings the possible risk or destruction during high stress and the duration of use.

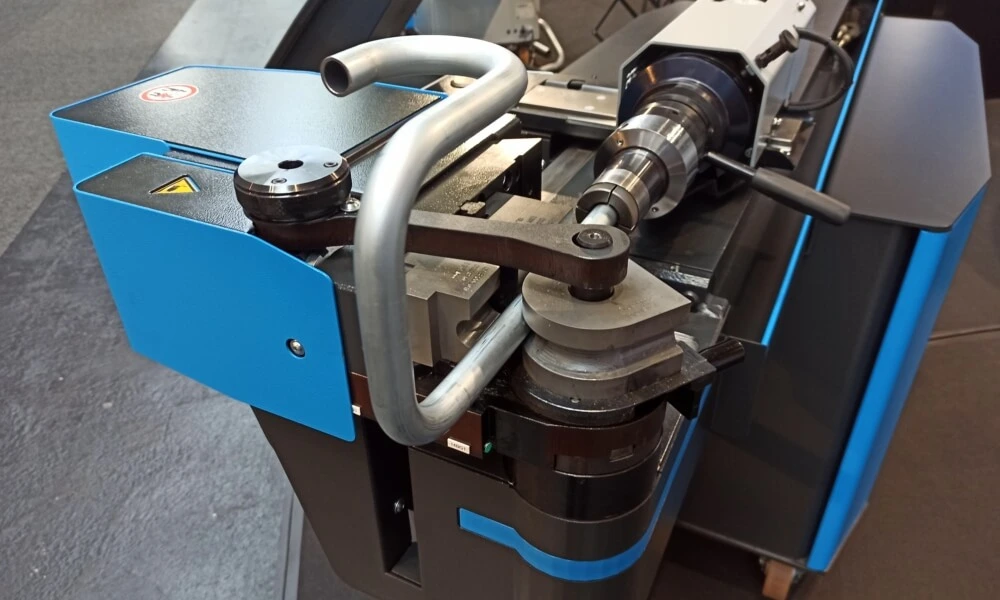

Tube bending tools

Also the note of tube bending tools for your new possible bending machine. With the use of special tools, it is possible to bring a lot of new possibilities in tube bending such as bending already formed tubes, after end forming, to make the bend in bend without the straight part and a lot of more things which can change completely the production process. But a lot of times these things do not request more technological or more expensive machines but just a correct and professional study of your project to prepare for you the best solution according to your request and your budget.

Our company stays separate from tube bending machine manufacturers but we know perfectly the market, possibilities and the technology. Normally we supply tools but we can provide also consulting and advisory services for tube bending applications to make your choice for the new machinery correctly and technically based with the elimination of risks for overpayment for the machine you do not need. Italy is also very famous for tube bending machinery and we have connections with many manufacturers to discuss the possible details and get the best offers.

Please take into consideration also the tooling engineering and request from the beginning all possible drawings for tools that you will purchase with the machine. It helps you to develop the new tools by yourself, contact independent tool makers, and verify all the prices. If the factory doesn’t have a stable product program or acts as a workshop (to offer tube bending services) the fact to obtain new tools for a good price is quite important. And we want to tell you that sometimes for the soft materials and small quantities, it is possible even to make 3d printing of some elements inside the factory without waiting for supplies from the tool maker.

This post is also published on @Medium