Well, probably this post looks more promotional, but we will try to make it more technical to tell more about Promecam press brake tools and, in particular, about 4V bending dies.

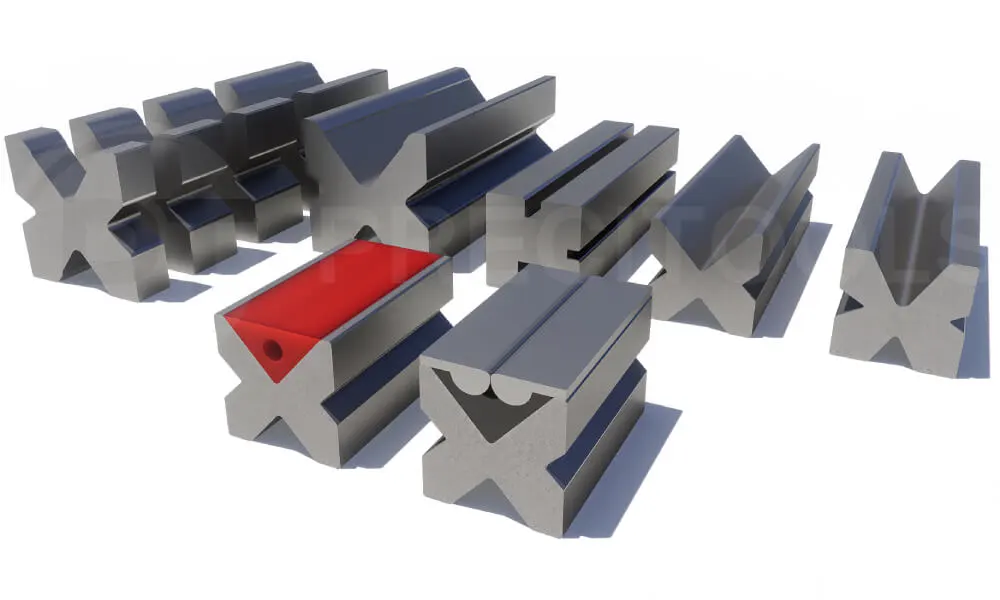

This is the most universal product and is mostly ordered by customers. It is usually supplied as a “starting set” with the new press brakes by the manufacturers.

A small story of invention: to make the tools more universal, even 60–70 years ago, there were a lot of inventions to put several die grooves into one tool. Moreover, the tools were full length only, so having all in one was very important. It was cheaper, and the operator didn’t have to replace the bending die itself, only to rotate. There were some ways developed for mechanical rotation as well.

A 4V bending die is based on the same principle: one tool with several grooves. But today it is available in sections as well, and you can install it on any modern press brake.

Promecam tooling system

To tell more about functionality, let us speak a little bit first about the complete system.

The Promecam system (or European type or Euro) for lower tooling has a 60 mm bottom width with a center in the middle; it means half, i.e., 30 mm. Bigger machines could also have die support for 90 mm, but 95% of the machines have 60 mm. Also, the Promecam system has fixation clamps for complete length. For the operator, it means that he can install the sectioned tooling. So even small pieces (10–15 mm) could be possible to install on the length and to clamp.

For the Promecam system, a 4V die is a standard article and product. For other systems (WILA, Trumpf, LVD, etc.), it is possible to install 4V bending dies with the use of adaptors.

Because the centerline is strict and only in the middle of the tool on the Promecam system, there are no Multi-V dies. It means that you cannot adjust V-openings toward the center. So four sides with one opening on each side for the bending die is the maximum possible.

It is quite good for different thicknesses to bend on your press brake to have one set of tooling for all. It saved a lot: time for tooling installation, the unnecessity to store additional sets, and finally, the money that was spent on the bending tooling!

For example, with V=50 as the maximum opening, you can work with a thickness of 6 mm. In theory, you can also work with a bigger thickness, but respect the maximum allowable tonnage of the tool.

Precitools 4V / 3U Multi-V bending dies for tooling system Promecam for press brake

Advantages of 4V bending die

4V die is quite good for all of this—you can cover all ranges you need. Unfortunately, there is no V8 or V10 to bend 1 mm thickness, but you can bend it with V16 with a bigger radius.

A 4V die with a height of 60 mm is the minimum possible height of the die for the press brake. This allows for the use of this die even for various manual press brakes, ironworkers, hydraulic presses, or bending equipment for garage presses. These machines and tools usually have very small or limited openings. It means that tall bending tooling is completely impossible to install and use.

For sure, there are a lot of limitations, such as the width of the die (so you cannot make small-distance Z-bends), height, and fixed openings. Meanwhile, it is the best product in terms of price-possibility value and is very popular for potential requests and orders.

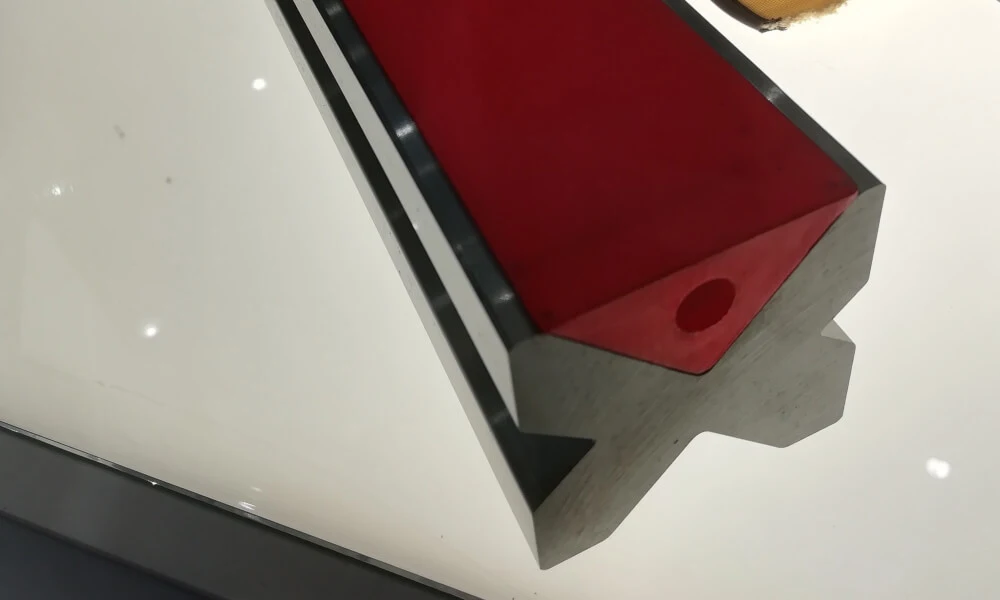

Also available is the triangle polyurethane insert to put in the V50 opening. It allows the additional radius bending inside the polyurethane—one more big advantage to use as the holder for inserts without any additional costs. There are also some individual solutions. For example, the roller insert to bend with a smaller opening and a small possible radius of bending.

Standard Precitools 4V bending die with polyurethane insert on the top

Standard 4V dies are available at 88 and 85 degrees. Are also available with additional types with 60 degrees and smaller openings—to bend thinner materials compared to the main one and even with an angle less than 85.

Different thicknesses with different die openings

We should speak in general about why press brake users should also have the possibility for more configurations with their tooling. A larger opening of the die with the same thickness allows the operator to reduce the tonnage of bending. The internal bending radius will be bigger, but it will be possible to bend thicker materials or reduce the limits if they appear. When you cannot enlarge the opening, you run the risk that some applications could be impossible for your machine. For example, if it is a low-tonnage press brake with 20–30 tons of force or a press brake without a complete force distribution.

But this is not only about the bending thickness. Some punches are quite fragile. To use them with medium thicknesses, you should go with a bigger opening—there is no other way. Otherwise, you have a risk of breaking your tools.

In the USA market, there are also such products for customers, like 4V dies as complete polyurethane pieces. In Europe, we don’t use such solutions. If it is necessary to eliminate marks and scratches, we can recommend to use the bending film on the bending die.

Under the request, we are also offering 4V dies with an external size of 90×90 with V-opening up to V = 70. We can offer special configurations and geometry as well.

During our experience, we know that the customer who purchases the new press brake usually knows nothing. For him, the bending process will contain a lot of challenges. For such customers, there is a big advantage to purchasing universal and simple tools—the zero risk of a mistake. It is quite a big problem if the customer makes some choices but later realizes that he needs other tools and new investments.

This post is also published on @Medium