The new process we would like to describe today is waterjet cutting. As we always noted, we are not connected to any sales of production machinery. So in our articles, based on our knowledge, experience, and cases that we have seen in factories, we are making our own separate review.

What is the technology of waterjet cutting

First, let us describe the main part. Waterjet cutting is the process of cutting flat materials with a water jet supplied with high pressure. Usually, the process of waterjet cutting is used for applications with “soft materials.” It means that materials like textiles, rubber, leather, foam, wood, probably some carbon fibers, plastic, etc. For all hard materials, including metals and stones, the process involves the supply of water under high pressure together with small particles of sand. This process is called “abrasive cutting,” “mixed waterjet cutting,” or “abrasive waterjet cutting.”.

The pure waterjet cutting process was known to the world until the mid-19th century. It was used in coal mines to perform the high-pressure flow of water with the use of steam power to remove clay and gravel. At the time, the high pressure value was enlarged, and in the mid-30s, waterjet technology was the first to be adopted outside of mining operations. The factory in Wisconsin used the waterjet process to cut the reams of paper. After several years, there were initial developments and ideas to add abrasive materials to the water fluid to look for cutting capacity for other materials. In the second half of the last century, waterjet cutting technology completely changed the process as we know it today.

Now let us speak more in detail. We already mentioned waterjet cutting as one of the technologies for cutting sheet metal before other operations such as press brake bending, but today we will try to make more explanations about only this technology itself and probably some comparisons to other cutting processes.

Waterjet technology is N1 for stone figure cutting

First, we will tell you that one of the main applications for waterjet machines is for producers and manufacturers of various types of stone plates to be used in buildings and decorations. For them, the waterjet cutting is completely the process of N1. It has any alternatives, with a lot of possibilities for any figure cutting as required. Also waterjet cutting has very good precision, can cut really big thicknesses, and has a very clean cut with no necessity for any other operations.

But because we are talking about sheet metal production technologies, we want to talk about waterjet cutting (for sure, here and after we mean cutting with sand) of sheet metal. And a small review of why to use waterjet cutting compared to other cutting technologies:

Advantages and excellence of waterjet cutting technologies

- Perfect precision for cutting.

- Possibility to cut enormous thicknesses, like a 200-mm plate, with optimal quality. With any other technology, it was nearly impossible. There are some technologies, such as gas-flame cutting, with very poor quality and precision. Compared with laser cutting machines before, the limits for CO2 lasers were 20–25 mm thick, but even now, if we speak about high-technology fiber lasers, even 80 or 100 Kw have the limits of cutting like 100 mm thick with not-so-clean cutting edges.

- Cutting in the cold without any thermal impact. It means that there is no thermal touch on the edge of metal to destroy or change the cellular structure of the material. This is very important in such fields as aerospace, chemical, medical, etc., where no change in material structure is permitted. Also, in some materials, cutting with thermal is also not possible, based on the fact that it destroys the edges, like foam or carbon fiber. So for it, waterjet will be the unique solution to perform the figure cutting.

- There are no differences in materials. For example, cutting copper and brass with CO2 laser cutting machines was a big problem in terms of reflection to not damage the mirrors, and there were possibilities only for very small thicknesses.

- Clean edge and no necessity for any cleaning or deburring operations. For sheet metal, even clean laser cutting or punching makes the small burr on the edge that is probably important to remove after.

Additional advantages

- Angular cutting – necessary for some applications. Mainly waterjet machines have 5 axes – X, Y, Z + 2 additional axes for head rotation. Together with high precision, it allows a lot of possibilities.

- No special ventilation and fumes extraction necessary – there are no toxic fumes during the process of waterjet cutting.

- No necessity for additional covers and protection panels for the equipment. No risks for visual contact like necessary eye protection for plasma and laser cutting machines to prevent any eye damage.

- No additional waste like molten metal stuck on the table grate or the table bottom thanks to cutting in cold.

- There are no necessities to clean the table grate or to have special equipment to take this action.

- There is no damage to the environment compared to thermal cutting.

Big motor section part made with waterjet cutting machine

On the Internet, there are videos for cutting complete gears and solid shapes which will be completely final part. Any other process of machining will cost more, investments will be more and probably the process will be slower. So in some applications, waterjet is a brilliant solution.

Disadvantages of waterjet cutting compare to other technologies

- Running costs cutting bigger compared to laser cutting for example. For sure it requires the comparison with details on the application.

- Today with so wide market of laser cutting machines investment costs to waterjet will be bigger in terms of purchasing of the machinery. Waterjet cutting technology is more expensive to buy the equipment. And it means it makes more expensive the price of the final part.

- Incredibly slow. It is even impossible to compare the speeds of waterjet because compared to laser cutting. It is slow not in times but a dozen times. Sometimes if possible for production, the operator put several sheets as a stack on the table for cutting to cut one sheet but five together. To enlarge the speed manufactures make multi-head cutting machines. It means that the machine will have the several cutting heads on the machine traverse to cut the same parts simultaneously.

- Sand abrasive waterjet cutting is not a completely clean process. A constant mixture of waste of sand makes water and mud thicken in the bin under the table.

- After the distance the jet becomes thicker so the precision will fall during the cutting of big thicknesses.

- Noise level during waterjet cutting could reach 90 dB.

- Laser cutting technology is much more used on the market for 3D cutting. Foe example, installation with robots or manipulators (for example to cut in 3D stamping parts), used for tube and profile cutting etc.

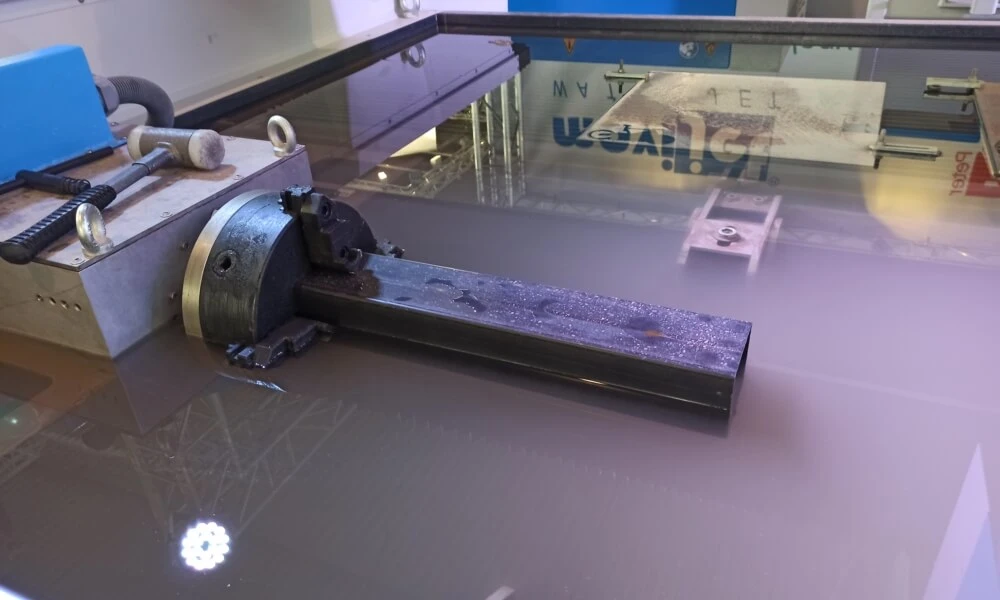

Rotatable chuck on waterjet cutting machine for cutting profiles and tubes with waterjet

Conclusion

We usually say that factory management is the most important factor in choosing the technologies based on the applications. For example, let us talk about classical sheet metal jobs where the majority of work covers 1–10 mm steel materials. The waterjet cutting machine will be a completely uninteresting technology for them.

For standard sheet metal workshops, the waterjet cutting machine is an expensive and very slow toy for thin metal cutting. It means that the investment in the equipment will be high, and the effect will not be reasonable. And finally, the price of each produced part will be enormously expensive.

But if we speak with the subcontractor of aerospace parts and a variety of materials to proceed, the waterjet cutting technology will probably be an excellent solution. Moreover, sometimes it is interesting to speak not about the complete parts but about the mixing of production technologies. For example, the making of contours and shapes of metal parts before further transfer to the milling machine for final work. Probably, in this case, the factory can optimize the processes, costs, and expenses for the parts to make their production more effective and competitive.